PRODUCT CATALOG

Hydrocyclone Filter

HCF 150CL Series

Design Features

A Hydrocyclone filter uses centrifugal force to seperate heavier particles from lighter particles. The tangential nozzle at the top induces a whirl which creates a centrifugal force. The heavy debris particles are pushed to the side walls and the lighter clean liquid flows out through the top outlet Nozzle. Filtration is further enhanced by the conical body which further accelerates the flow and increases centrifugal force.

Features

- Vessels are designed to ASME SEC VIII Div – I

- Max. Pressure 120 psi

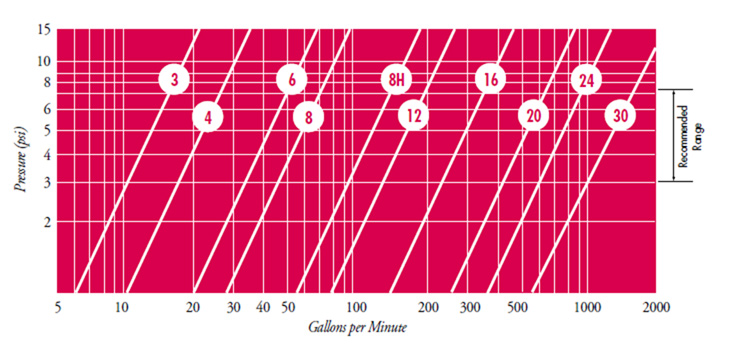

- Min. head loss for effective operation 3 to 8 psi

- Conical body accelerates flow increasing centrifugal force and enhances filtration

- Reduced flushing frequency due to large debri chamber

- Debri Handhole is standard, Clamped cleaning port on request

- Manual butterfly valve for flshing is standard

- Motorized butterfly valve with control timer can be supplied on request

- Rubber cones for sizes higher than 14″ is standard to avoid errosion of the neck

- 100 micron polyster oven-curved protective coating with zinc sulphate under layer

- ANSI, DIN, IS connection flanges can be supplied

- CS TO IS 2062, SA 516 GR 60-70,SS 304,SS 316 Materials of Construction

- Nozzels can be of CS TO IS 1239/3589 , A106, SS304,SS316 MOC

Applications

- Seperation of sand and other solids from water

- Pre filtering of water with high loads of sand before sand before secondary filters

- Protects pumps valves and other capital irrigation equipments from abration from by debris

Installation and Operational Guidelines

- Debris chamber must be drained when it is 1/3 rd full

- Flow at the outlet should be throttled to 3 to 8psi for effective fitration

- The flow has to be constant by and large for the filtration to be efficient

- Hydrocyclone filters are required when the turbity is 2 to 20ppm

- An automatic drain valve is recommended to when the ppm is high

Dimensions

| Line Size B nb |

Min Flow lpm |

MaxFlow lpm |

D nb |

C nb |

L mm |

T mm |

H1 mm |

H2 mm |

W nb |

H3 mm |

|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 35 | 60 | 75 | 20 | 120 | 32 | 260 | 325 | 250 | 150 |

| 25 | 36 | 125 | 100 | 25 | 150 | 40 | 330 | 400 | 250 | 150 |

| 40 | 126 | 200 | 150 | 40 | 235 | 65 | 495 | 545 | 350 | 200 |

| 50 | 201 | 285 | 200 | 50 | 300 | 75 | 580 | 615 | 350 | 200 |

| 80 | 286 | 570 | 250 | 80 | 300 | 105 | 675 | 735 | 550 | 790 |

| 100 | 287 | 1370 | 400 | 150 | 595 | 130 | 875 | 1480 | 750 | 890 |

| 150 | 1371 | 2660 | 500 | 200 | 595 | 165 | 1150 | 1610 | 750 | 1370 |

| 150 | 2661 | 3800 | 600 | 200 | 595 | 215 | 1405 | 1860 | 750 | 1370 |

| 200 | 3801 | 6080 | 750 | 200 | 700 | 265 | 1940 | 2210 | 750 | 1370 |

Hydrocyclone Headloss

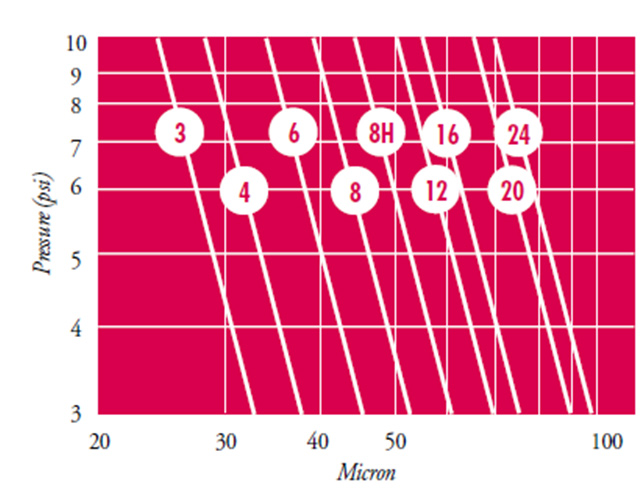

Hydrocyclone (Particle Size Separation in Micron)

NOTE: The Micron chart is based on sand with a specific gravity of 2.7 gr/cm.