PRODUCT CATALOG

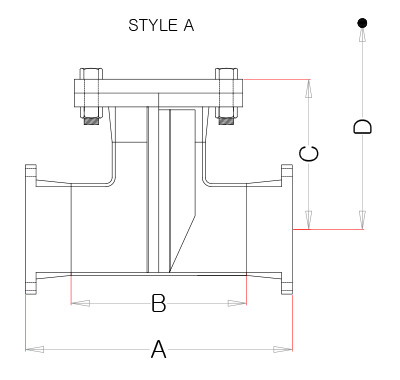

T Strainer Style A Series

Design Features

- Standard sizes from 2” – 24”. Larger sizes available upon request.

- Available with RF flanged ANSI B16.5 or Butt welded ends

- Standard thru bolt cover design.

- 304 SS perforated screens are standard.

- May be installed in horizontal or vertical pipelines.

- All welders are qualified to ASME Section IX.

- Strainers designed to meet the requirements of ASME B31.1, ASME B31.3 and / or ASME Section Viii, Div. I.

- Drains, vents, differentials and pecial covers are optional.

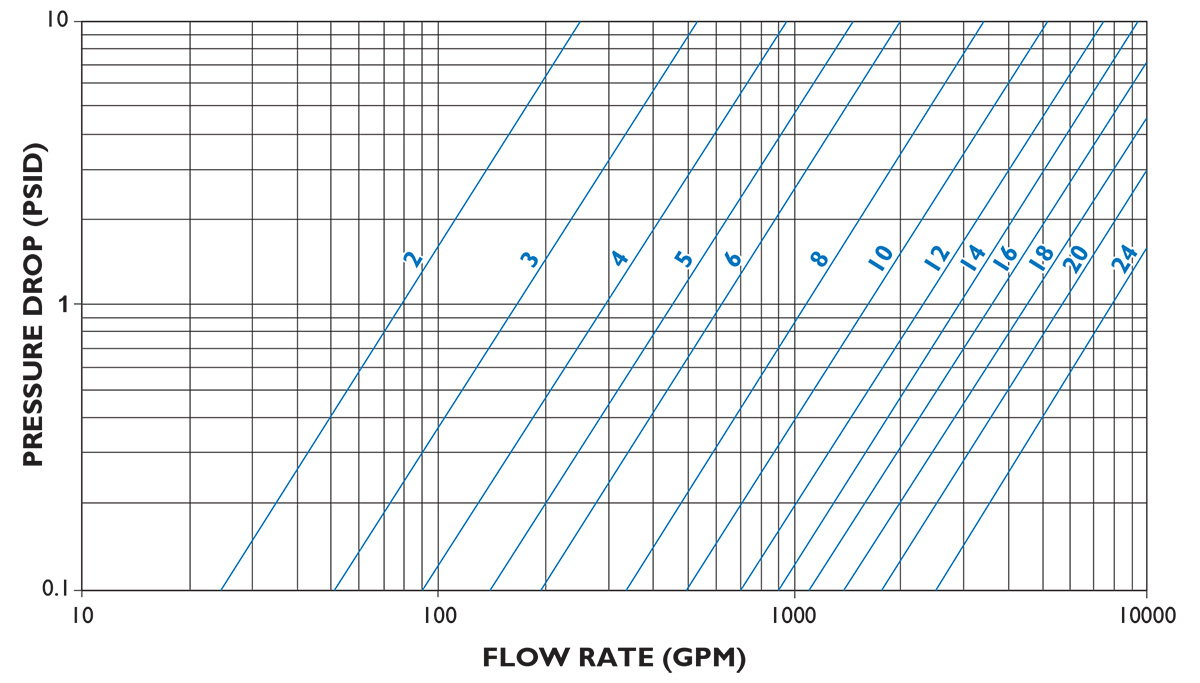

- Pressure drop as per Table-2

- End and cover flanges can be supplied as Slip on

Material Data

| Body | A234 Gr WPB/ CS TO IS1239/3589 / ASTM A106/SS304/ SS316 |

| Cover | CS TO IS 2062, ASTM A105, SA516 Gr60/70, SS304, SS316 |

| Connection Flanges | CS TO IS 2062, ASTM A105, SA516 Gr60/70, SS304, SS316 |

| Fasteners | A193 Gr B7, CS TO IS 1367, Stainless steel |

| Gaskets | Neoprene, Nitrile rubber, CAF, Teflon, SS304/316 Spiral wound |

* Other materials available on request.

Standard Screens

| Size Range | Opening | Guage Thickness |

|---|---|---|

| 2″-8″( 50mm-200mm) | 0.125 IN. (3.2mm) | 22 |

| 10″-12″(250mm-300mm) | 0.125 IN. (3.2mm) | 16 |

| 14″-24″(350mm-600mm) | 0.188 in. (4.8mm) | 11 |

Dimensions

| Size mm |

A mm |

B mm |

C mm |

D mm |

|---|---|---|---|---|

| 50 | 254 | 127 | 146 | 279 |

| 80 | 311 | 172 | 179 | 349 |

| 100 | 362 | 210 | 205 | 413 |

| 125 | 425 | 248 | 237 | 489 |

| 150 | 464 | 286 | 257 | 540 |

| 200 | 559 | 356 | 305 | 660 |

| 250 | 635 | 432 | 348 | 762 |

| 300 | 737 | 508 | 400 | 889 |

| 350 | 813 | 559 | 441 | 991 |

| 400 | 864 | 610 | 468 | 1067 |

| 150 | 965 | 686 | 522 | 1194 |

| 500 | 1051 | 762 | 568 | 1305 |

| 600 | 1168 | 864 | 632 | 1473 |

Fabricated T Strainer Pressure Drop — Liquids (Sizes 50-600mm)

Note: Pressure drop curves are based on water flow with standard screens.